3 steps for the maintenance of your spray nozzles (and common mistakes to avoid)

Crop protection products can only be effective if applied properly. Cleaning your sprayer is not enough to ensure optimal operation: frequent maintenance of your sprayer and nozzles is essential to extend the lifetime of your equipment. Here are some tips from TeeJet and Kramp!

Poor performance of your nozzles increase the risk of under- or over -applying performance. This can lead to yield loss, chemical waste and reduced profitability. Worn out nozzles can lead to losses for thousands a year. How to clean and fix the spray nozzles?

Recognize the reduction in spray performance

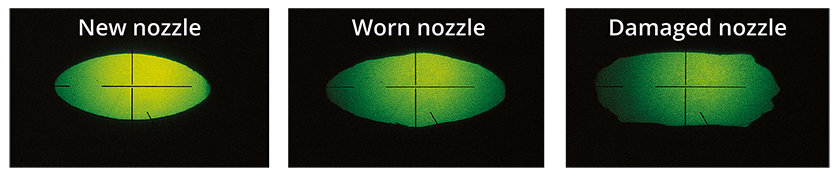

Spray nozzles don’t last forever. Yet it is extremely difficult to detect wear. Because it may not be visible. Spray nozzle wear of 10, 20 or even 30% won’t be visible. Special optical equipment would be required to actually see changes in the orifice size. So rather than relying on visual inspection, you should compare the flow rate from a used nozzle with the flow rate from a new nozzle of the same size and type. How to detect wear on your nozzles?

- Check the flow rate. Monitor flow meter readings to detect increases, or measure the volume of the spray from the nozzle for a given period of time at a specific pressure. Then compare these readings to the flow rates listed in the manufacturer's catalog or compare them to flow rate readings from new, unused nozzles.

- Check the spray coverage. Nozzle wear and nozzle alignment can cause issues for uniform spray coverage – check both when coverage begins to be an issue.

- Check the spray pressure and volume. Nozzle wear can be reflected in the spray pressure and the spray volume. With centrifugal pumps, monitor for increases in liquid volume sprayed. With positive displacement pumps, monitor for pressure decreases. The TeeJet sentry tip flow monitoring system detects variations in flow per nozzle and is very fast and accurate.

- Watch for larger droplet sizes. Drop size increases cannot be visually detected in most applications. Examine the application results for changes. Also, note that increases in flow rate or decreases in spraying pressure will impact drop size.

Types of damage

Crop protection products, spray mix, wear (erosion or corrosion) or dirt affect how nozzles wear and their tendency to clog. These are 7 types of damage that can degrade spraying efficiency:

- Wear/erosion

Most nozzles are manufactured in a hard-wearing material. Higher operating pressures also result in faster nozzle wear. So any nozzle tip can erode rapidly due to abrasion. - Corrosion

Nozzle material can wear due to the chemical reaction of the liquid being sprayed or the type of environment in which the nozzle is exposed. - High temperature

Breakdown of the nozzle material due to the elevated temperatures of the fluid, the surrounding environment, or both. - Caking/bearding

Build-up of material around the inside or outside of the nozzle. - Clogging

Unwanted particles from the liquid being sprayed which become lodged in the nozzle tip. - Accidental damage

Physical damage to the nozzle caused by hitting trees or cleaning the nozzle with inappropriate tools. - Improper assembly

Nozzles with accessories – caps, gaskets, o-rings, valves - can be installed incorrectly.

While wear may not be detected when visually inspecting a nozzle, it can be seen when viewed through an optical comparator.

While wear may not be detected when visually inspecting a nozzle, it can be seen when viewed through an optical comparator.Regular maintenance

Take time to check for wear, clean and rinse the clogged nozzles with a cleaning brush and use a line strainer, or built in nozzle strainer. Rigorous cleaning may do more harm than good. If cleaning is difficult or potentially damaging, consider soaking the nozzles in a mild solvent to loosen debris. Be sure to use the right materials. Clean your nozzles with items softer than the surface. Plastic bristle brushes and/or wooden and plastic knives are ideal. DO NOT use wire brushes, pocket knives, welder's tip cleaning rasps or anything harder than the surface of the orifice.

Replace your spray nozzles

If you think there is a nozzle that may better meet your needs, or you suspect that your nozzles are worn, do not hesitate to replace them. The cost of replacing nozzles is minor compared to the effects of poor spraying. Here are a few tips:

- Do the math. Sprayed solutions have associated costs. Calculate how much your worn nozzles are costing you in wasted water and chemicals versus replacing them.

- Consider the cost. Product quality has a high value. Determine what the deteriorating quality on your finished product or application will cost. These costs could include scrap, product rework and customer service problems.

- Set a trigger point. Nozzle wear has its limits. Identify a specific flow rate increase or pressure decrease that signals it is time to replace your nozzles.

The TeeJet SpotOn nozzle calibration tool provides fast insight in the actual Liters/minute flow rate of a nozzle. Alternatively a calibrated container and a stopwatch can be used. Based on the nominal flow you can calculate the percentage deviation. It is recommended to replace nozzles with a deviation of 10% or more.

If you regularly maintain your nozzles, you will avoid problems and a loss of profit. Do you want to know more about this topic? Contact our specialists.