How do you prevent damage to pneumatic tools and pneumatics due to moisture in the compressed air?

Many companies - from large agricultural organisations to small independent entrepreneurs - use compressed air for tools and pneumatics, among other things. The compressed air is needed to drive tools or to inflate tyres. How do you prevent moisture from ending up in compressed air, especially now that it is damper outside because it is getting colder? In this article we have explained this for you in a few steps.

Step 1

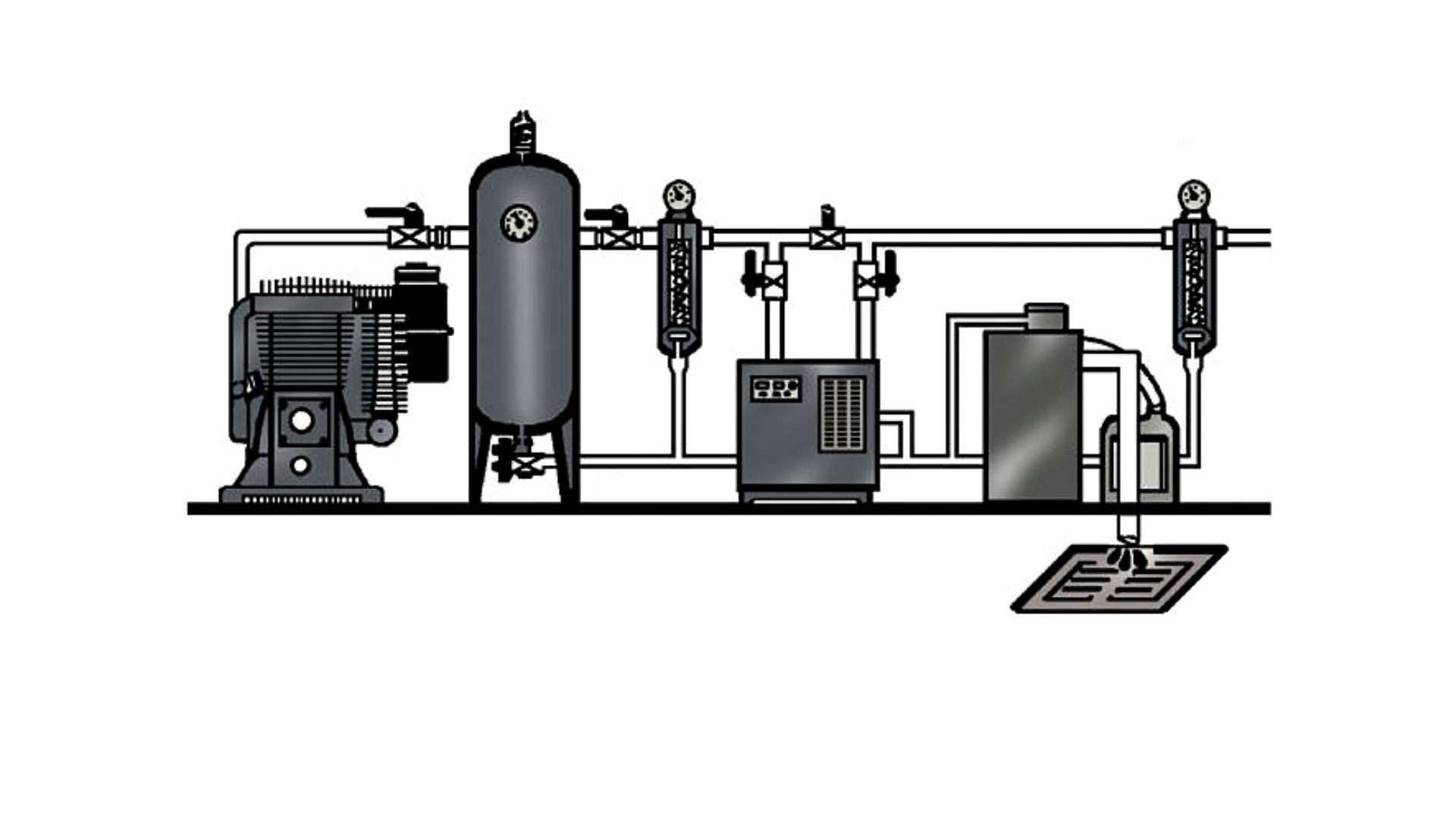

A compressor compresses the compressed air and stores it in a boiler. Among other things, the compressor sucks in debris and moisture from the outside air. Not everyone has a good idea of the consequences of this. The air stored in the boiler condenses. It is often forgotten to drain the resulting water. Too much water leads to rust, for example. To prevent this, or other forms of damage, use an (automatic) condensate drain. You use this to drain off condensation at the bottom of the boiler. Take a look at the range of special (automatic) condensate drains.

Step 2

Water, water particles or condensation can then be separated from air behind the outlet of a boiler. For this purpose you install a cyclone water separator, where the air first passes through the separator at high speed through the side. This causes the drops to fall down, where the water is drained off. View the range of cyclone water separators.

Step 3

When air cools down, more water is created. To prevent unnecessary condensation during the colder days, install a Freon compressed air refrigeration dryer. This equipment cools air to a dew point of 4 degrees. This means that all the water up to that temperature is out of the compressed air. Here you will find the range of compressed air refrigeration dryers.

Step 4

All the water drawn off from the compressed air contains oil. This is caused by the oil-lubricated compressor. This polluted water must not end up in the sewer: penalties are therefore imposed for this. To prevent this, install an oil-water separator. This separates the water - originating from the compressed air - from the oil by means of filters, so that the water can legally be discharged into the sewer. View the range of oil-water separators.

Do you have any questions?

If so, please contact a Kramp product specialist or contact us at knowledgecenter@kramp.com. Curious about all the air care products we sell? Then take a look at our webshop.