How to find the right respiratory protection in 5 steps

Which respiratory protection do you choose in which situation? With the selection guide below it becomes easier to make the right choice.

How do you choose the right respiratory protection equipment?

Step 1: Check the safety standards

Any safety equipment you buy in the UK and Northern Ireland, including respiratory protection equipment, must be approved and carry the CE mark, which will be followed by a four-digit code.

Under European legislation, all respiratory protection equipments must be tested and certified to European Standards (EN). Below is a list of the most common EN standards for approved respiratory protection.

- EN 149: Filtering fine dust mask against particles, single use

- EN 405: Filtering half-face mask with valves against gases or gases and particles, single use

- EN 140: Half-face mask reusable, for use with filters

- EN 136: Full-face mask, reusable for use with filters

- EN 12941: Motor unit with helmet or hood against particles, gases and vapours

- EN 12942: Motor unit with full- or half-face mask against particles, gases and vapours

- EN 270: Breathing device for compressed air with hoods

- EN 139: Breathing device with compressed air for full- or half-face mask

- EN 137: Breathing device with compressed air for full- or half-face mask (bottle air)

- EN 12021: Compressed air must meet as breathing air.

Step 2: Identify the risk

Can you readily recognise and identify the dangers: dust, smoke, mists, gases, vapours ...? Dust is created when solid material is processed into smaller particles. For example, when drilling, grinding, sawing. The finer the dust, the longer it floats in the air where it can be inhaled.

Mists are formed by fine liquid drops, for example during spraying or cleaning under high pressure. Many mists also contain fumes. Welding smoke is created when metals are heated and then quickly cooled and oxidised again. Vapours are generated when a liquid or solid evaporates due to heating. A gas is a substance that is neither solid nor liquid at room temperature and pressure.

Ask yourself the following questions to properly identify the risks:

- Which substances are present in the air?

- In what concentrations do these substances occur? What are the threshold values?

- What properties do these substances have? The nature and circumstances of the work are also important;

- For how long will a worker be working in the environment or space?

- Are they performing one-off tasks or are these activities that occur regularly?

- Is there sufficient freedom of movement?

- Does it involve heavy physical work? In combination with wearing respiratory protection, this will be extra tiring.

Pay close attention to personal characteristics. The fit of any face mask is important. In addition, beards, even a stubble beard, create the risk of edge leaks in the event of dependent respiratory protection, thereby seriously reducing protection.

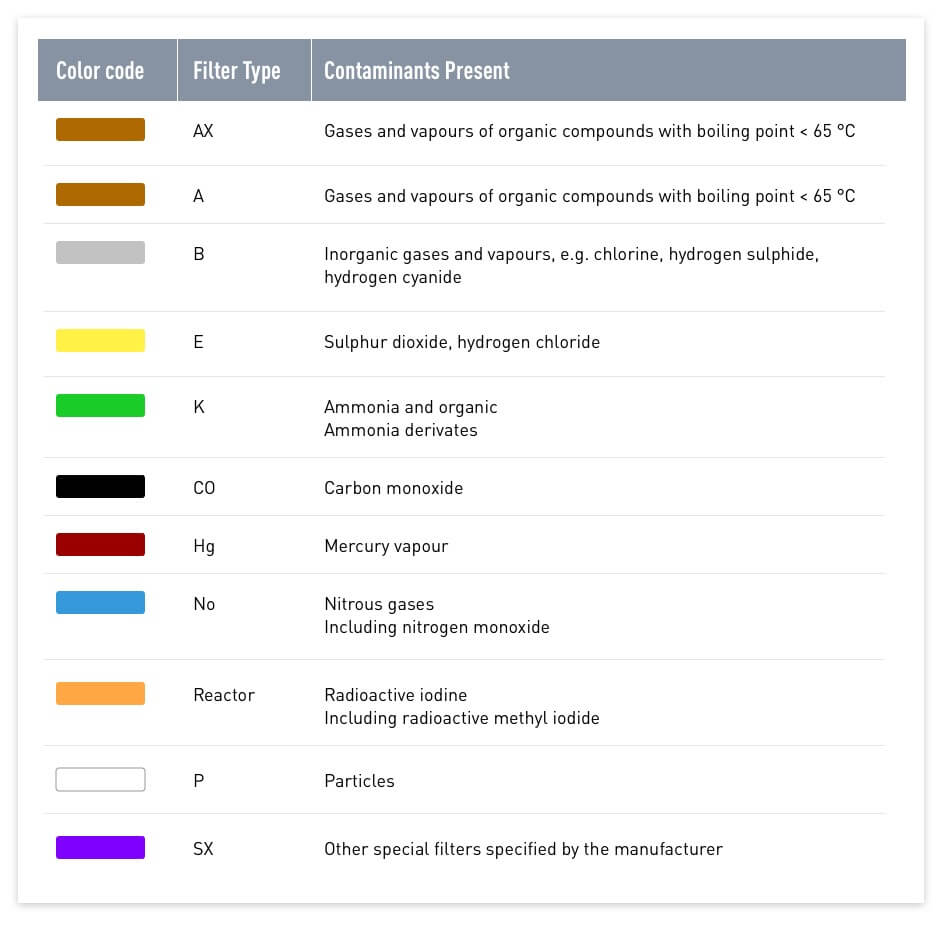

The following table shows the colour coding of the filters according to EN14387 - this helps you to determine what type of filter is required for the hazardous substance you are dealing with.

Colour coding for filters

Colour coding for filtersStep 3: Evaluate the risks

The next step is to assess all breathing-related risks. How likely is each risk to occur? How many employees are at risk and what are the consequences? It is therefore important, among other things, to identify the pollutants and to measure the origin and concentration to which the employees are exposed. Also take into account other factors such as breathing rhythm (oxygen consumption), individual sensitivity, environmental factors (humidity and temperature), etc. We recommend all employers begin with a COSHH assessment; you will find a step-by-step guide to conducting risk assessments in line with the Control of Substances Hazardous to Health Regulations 2002 here.

Step 4: Select the appropriate respiratory protection

You should now have sufficient insight into the risks and dangers of the environment and its contaminants, so it's time to choose the right respiratory protection. There is a solution for almost all risks and applications, and a large range available. If you have completed the steps above correctly, and assessed the environmental risk carefully, your choice of suitable masks will already be a lot smaller. The types of respirator available include: disposable half-mask respirator; reusable half-mask respirator, full-face mask respirator; fan-powered reusable full-face mask respirator; and fan-powered respirator with a reusable hood, visor or helmet. There are also various breathing apparatus types which may be required, ranging from compressed airline breathing apparatus with a half-mask through to powered, compressed airline apparatus with a full-face mask and hood.

Step 5: Make sure it fits to perfection

Respiratory protection is personal. Every working environment is different and no face is the same. Glasses, headwear, face shape, facial hair and even scars can all affect the quality of the fit. And in hazardous environments, it is critically important that face masks are extremely well fitted. In the UK, it is also a legal obligation...

For that reason, we advise downloading the HSE’s Fit Testing Guidance INDG 479. The British Safety Council has also launched a programme to help you choose a reputable fit test provider: www.fit2fit.org.

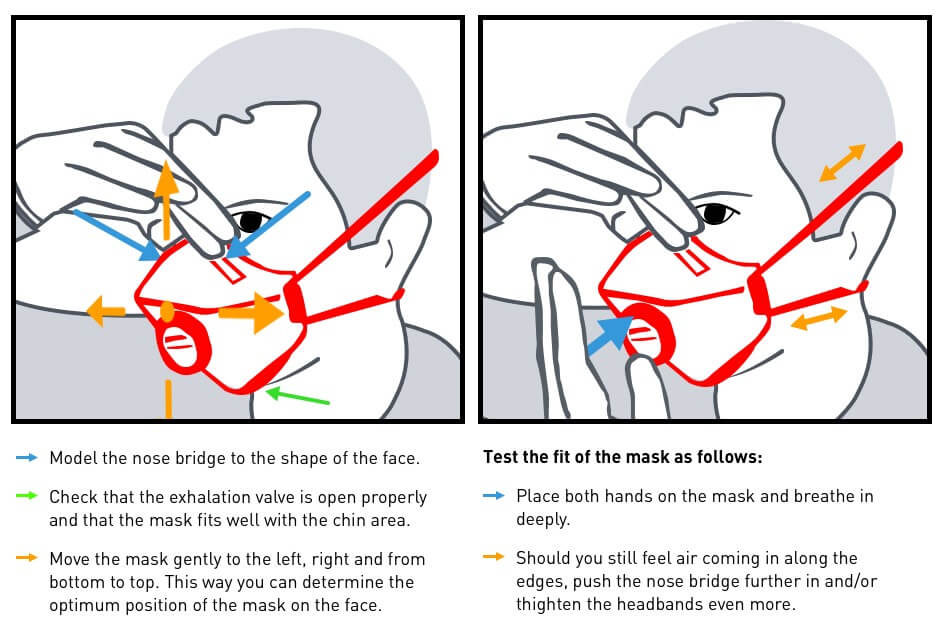

How to put on your mask

How to put on your maskNew technologies

Protective face mask technology is getting better every year. For example, there is a half-face mask on the market where employees can check with one movement whether the mask is in place, for extra confidence during work.

Would you like to know why respiratory protection is that important for your health? Read it in our article. If you have any questions at all about filtered masks or other protective products, feel free to contact us or get in touch with your nearest Kramp representative or dealer.