How to reduce spray drift when applying crop protection products

When applying crop protection products spray drift is a big challenge: it can have negative effects on your production costs, safety and the environment. Crop protection products can not only cause damage to surrounding areas, but can also end up in the waterways. Care, attention and knowledge about spraying agricultural products – and how to apply the product – is key. What is the impact of droplet size and pressure when applying crop protection products? Spraying expert TeeJet and Kramp share their insights!

What is spray drift?

The undesirable movement of spray droplets of crop protection material outside the target area by the wind or other factors is called drift. These five factors affect spray drift:

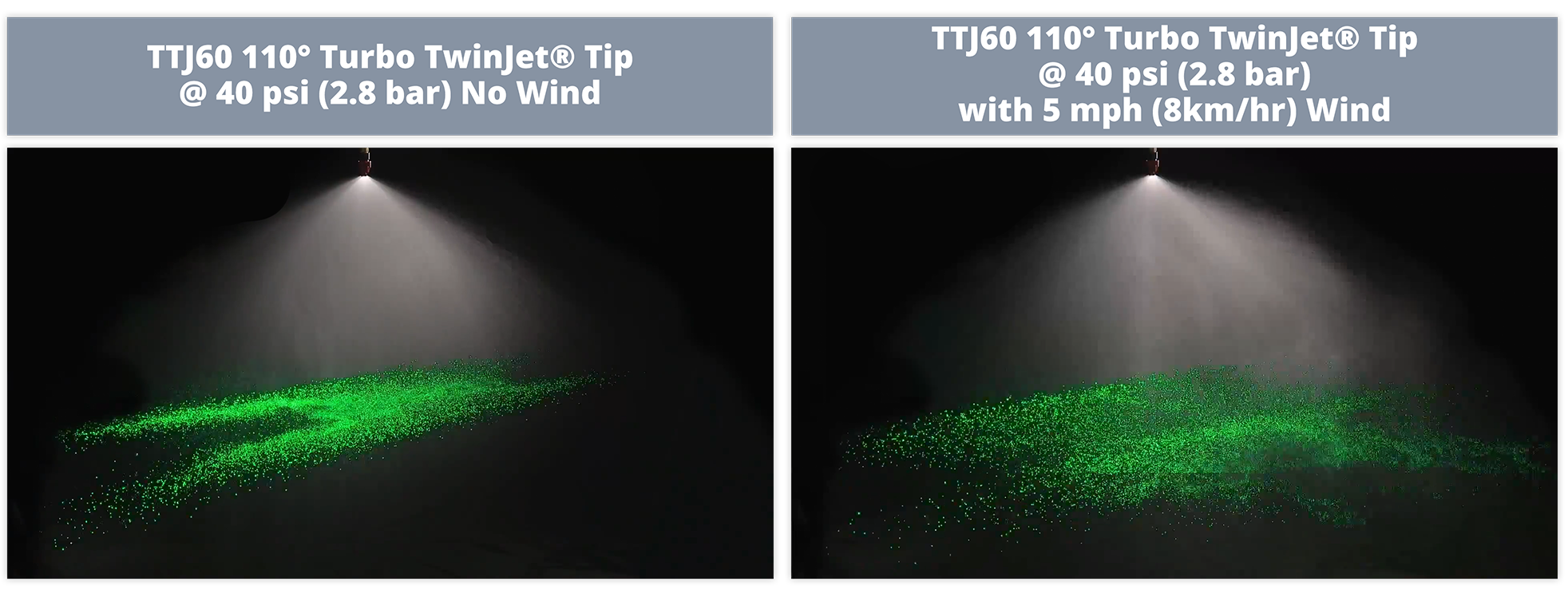

- Wind speed: Wind velocity and direction have a big impact on spray drift.

- Spray height: Increasing spray height from 50cm above the target to 70cm can result in up to four times as much crop production products to ‘drift’. The greater the distance between the spray nozzle and the target area, the bigger the impact wind velocity can have on drift.

- Temperature: A temperature inversion layer - a situation where the air temperature is cooler near the earth’s surface than in the air above it - can lead to spray drift.

- Droplet size: Low application rates usually require the use of small nozzle capacities, increasing the risk of drift. The smaller nozzle capacities normally result in smaller droplets.

- Operating speed: At what speed do you drive?

The importance of droplet size

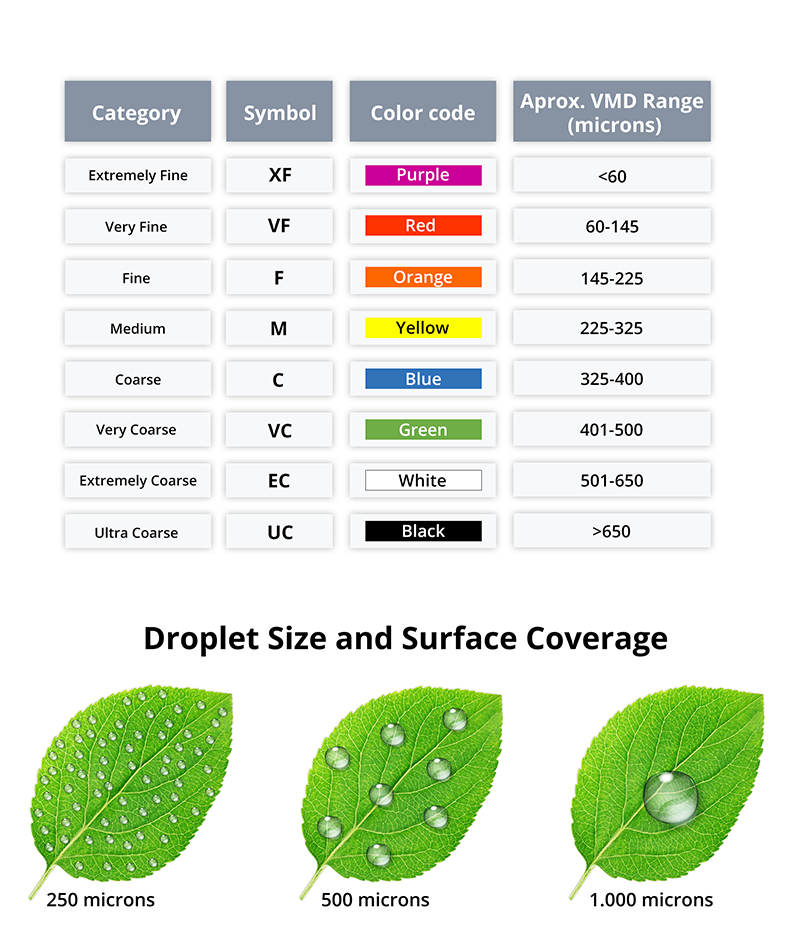

Droplet size refers to the diameter of an individual spray droplet. Droplet sizes are usually measured in microns (micrometers). One micron equals 0.001 mm. The micron is a useful unit of measurement because it is small enough that whole numbers can be used in drop size measurements.

The majority of agricultural nozzles can be classified as producing either fine, medium, coarse, or very coarse droplets. A nozzle with a coarse or very coarse droplet is usually selected to minimize off-target spray drift, while a nozzle with a fine droplet is required to obtain maximum surface coverage of the target plant.

Droplet size is a key factor in nozzle selection:

- When coverage is crucial, such as in post-emergence contact applications, nozzles with finer droplets are used because of the excellent coverage on leaf surfaces.

- Nozzles producing mid-range droplets are most commonly used for contacting systemic herbicides, insecticides and fungicides.

- Nozzles that produce extreme to ultra coarse droplets are usually used for systemic herbicides and pre-emergence soil applied herbicides while minimizing drift.

- Remember, droplet size can vary based on pressure. The same nozzle can produce medium droplets at low pressures and fine droplets at higher pressures. Check the overview below.

Droplet Size Classification

Droplet Size ClassificationImportance of the type of nozzle

With the right TeeJet Nozzle it’s possible to achieve 90% drift reduction. Low-drift nozzles are classified into drift reduction classes according 50%, 75%, 90% and 95%. Drift depends on the type of nozzle and the pressure used with the nozzle. By lowering the pressure, a higher drift reduction can – in some cases - be achieved with the same nozzle. Example: the TeeJet Nozzle TTI60 at 4.5 bar is 50% drift reducing. The same nozzle is at 2 bar 75% drift reducing and at 3 bar 90% reducing. It’s not possible to use any nozzle you want in every situation.

It’s not possible to use any nozzle you want in every situation, this can vary from country to country. Please check the admission list if there are restrictions for your use.

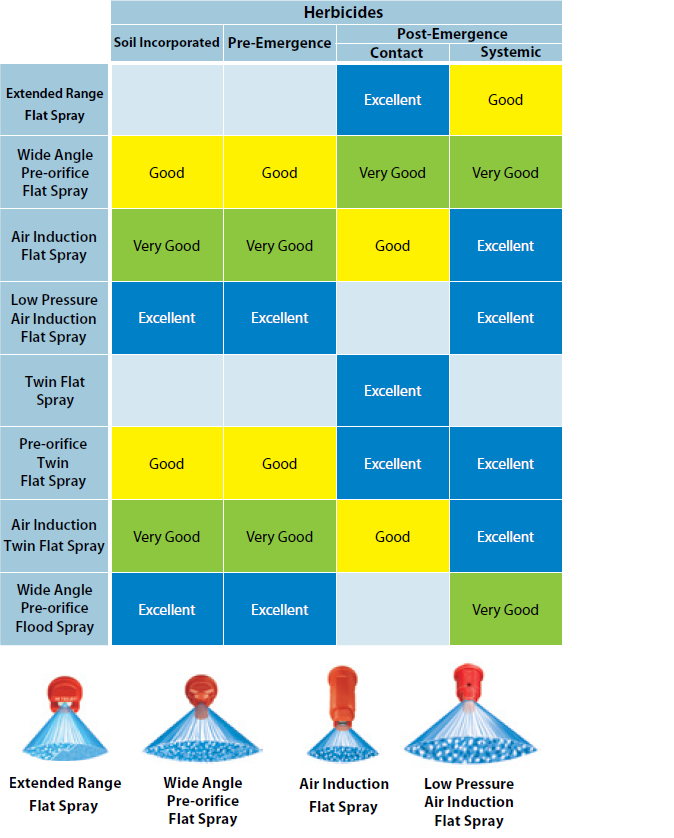

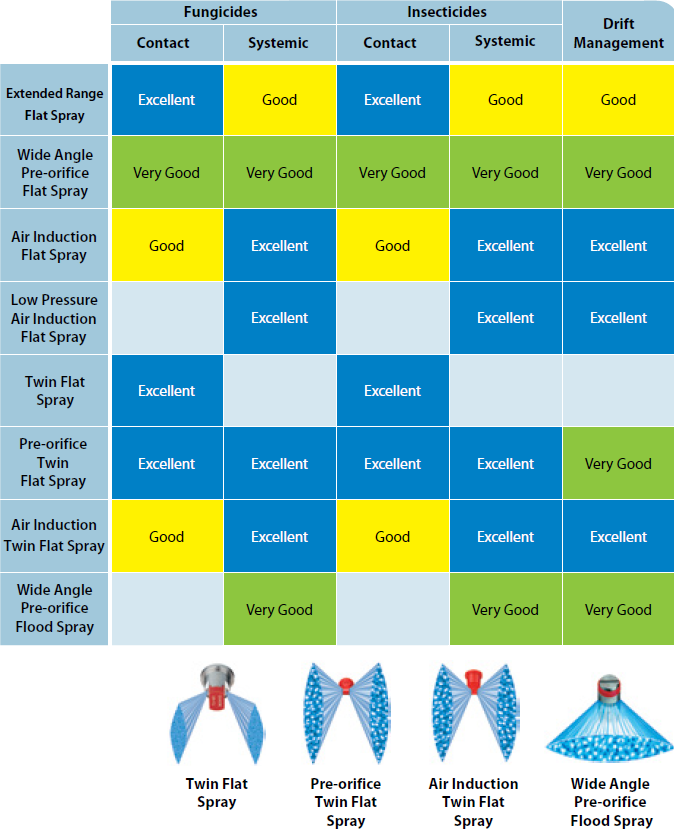

Choosing the right nozzle

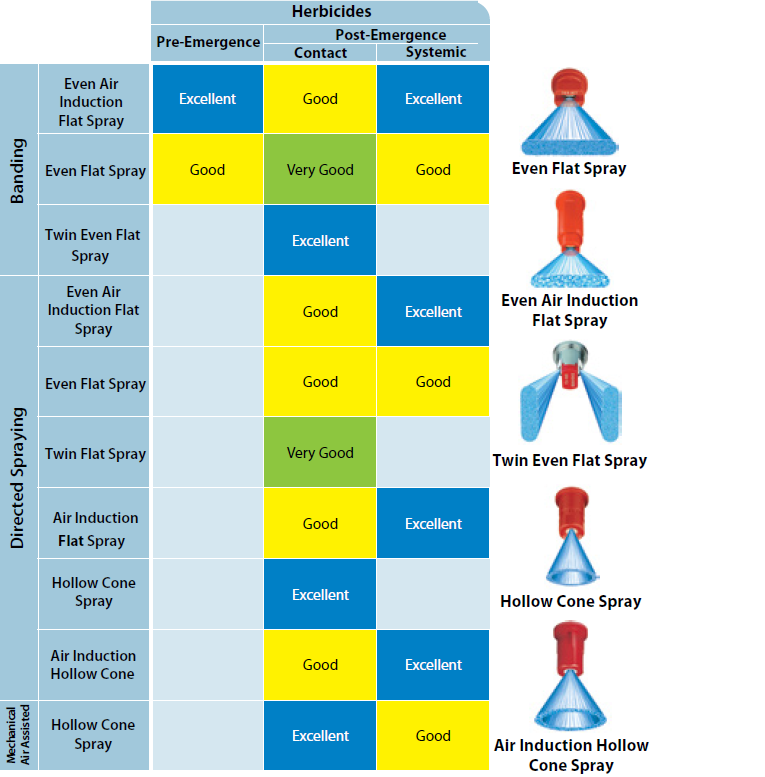

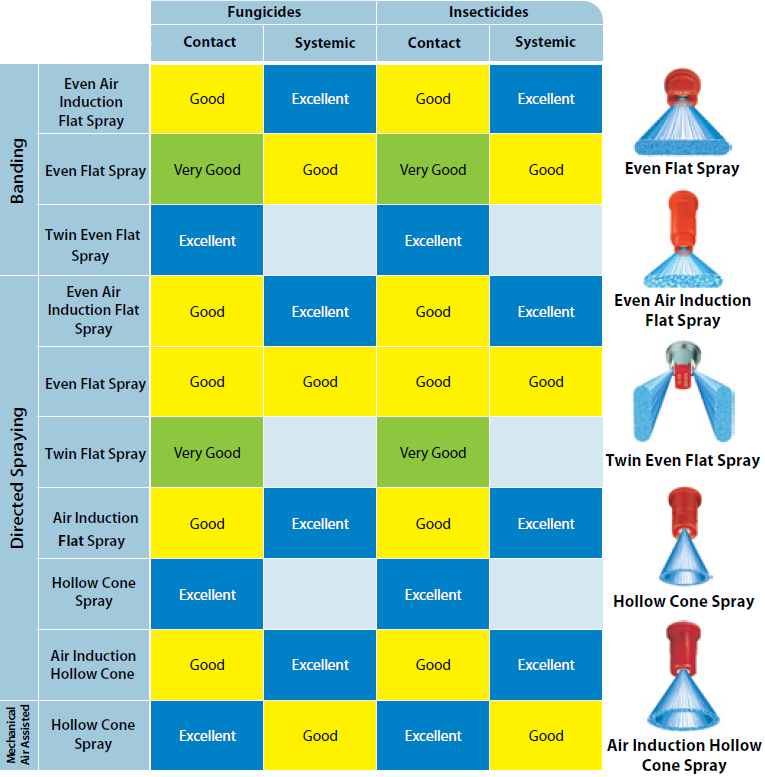

How to select the right nozzle to reduce drift? We’ve provided you with an overview of the options in the table below.

Do you have a question or do you want to know more about this topic? Please feel free to contact us.