Every hydraulic system powering agricultural and construction machinery includes a number of hydraulic filters, each specifically designed to remove contaminants and particles and protect the expensive equipment. While filters can be found at a number of locations along hydraulic oil’s journey through the system, it’s rare to find machinery which uses every type of filter. Each machinery manufacturer balances cost and physical constraints against the most efficient way to protect the system, and chooses which filters to include accordingly. When it’s time to replace the hydraulic filters, it’s important to know the differences and understand the importance of quality and the level of filtration.

Here, hydraulic filter specialists Donaldson, whose products can be found on the Kramp webshop, helped our specialists compile a quick and easy guide to hydraulic filters.

What are the types of hydraulic filters?

The following are the most common filters featuring in hydraulic system circuits. Pressure, location in the system and the pressure rating of each filter are important considerations.

o Low-pressure filters

o Medium-pressure filters

o High-pressure filters

o In-tank filters

o Breathers

Low-pressure filters

These will be found in most hydraulic systems, generally in-line on the return journey to the tank/reservoir towards the pump.

Low-pressure hydraulic filters are typically rated for pressures of up to 20 bar / 350 psi.

Low pressure filter

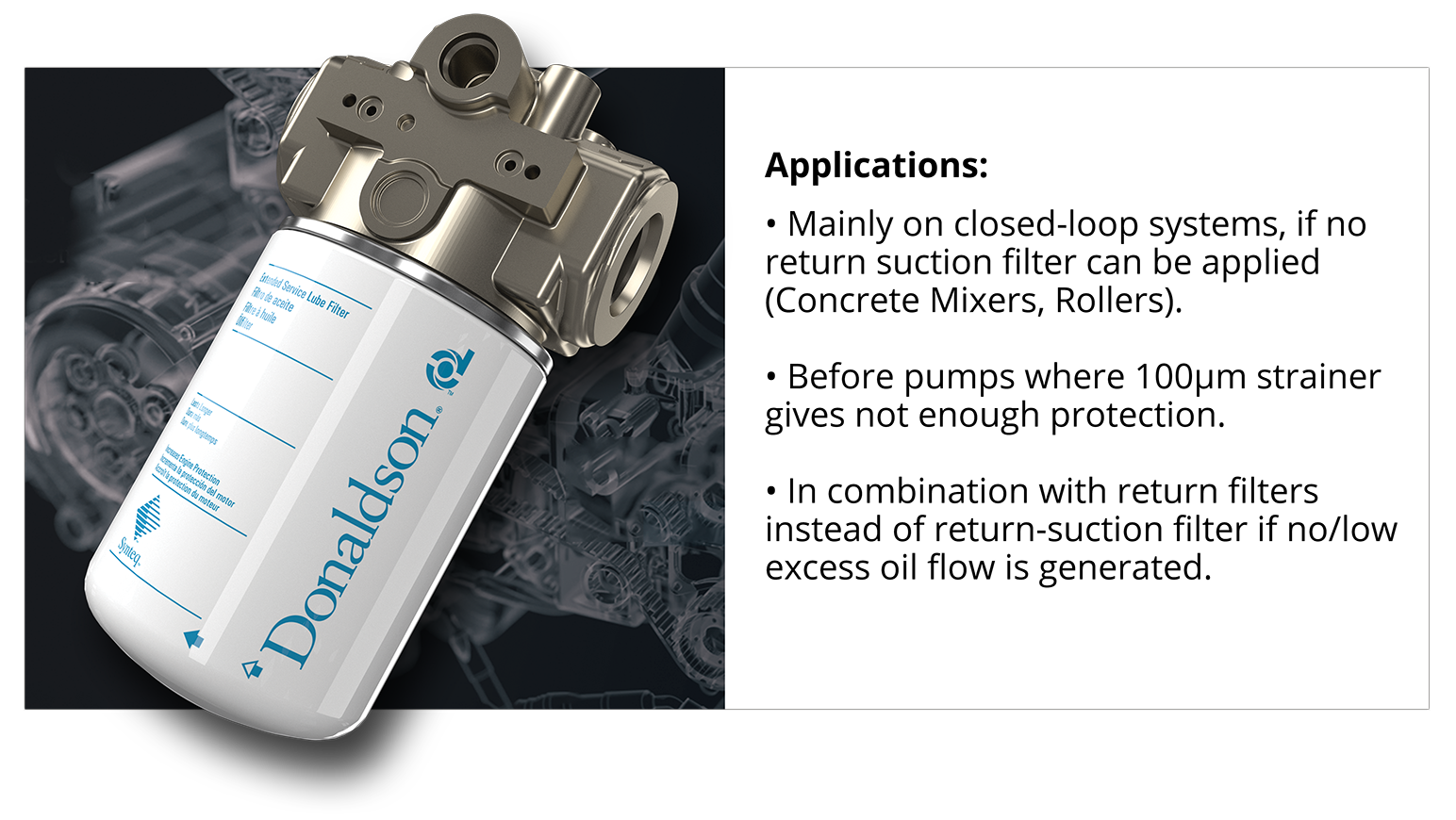

Low pressure filterMedium-pressure filters

Medium-pressure filters are usually designed as in-line components, with spin-on and in-line cartridge options available.

They are usually rated for use at pressure levels of 20-130 bar / 290-1885 psi.

Medium pressure filters

Medium pressure filtersHigh-pressure filters

These are usually placed between the pump and components like motors, cylinders and valves, for maximum protection.

They are typically rated for pressure levels upwards of 130 bar / 1885 psi and as high as 450 bar / 6527 psi.

High pressure filter

High pressure filterIn-tank filters

In-tank filters are low-pressure filters for the reservoir or tank; a space-saving design which positions on top of the tank, the cartridge inside, for return and suction line filtration.

In-tank filter

In-tank filterBreathers

Breathers are filters designed to maintain clean airflow in and out of tanks and reservoirs by preventing airborne particulate contamination and, in some cases, moisture contamination.

Breather

BreatherThe critical importance of pressure and efficiency ratings

Any filter you consider has been designed to handle a certain level of pressure, depending on its location in the hydraulic circuit. A filter positioned between the tank and before the pump, for instance, is low-pressure-rated, because no pressure is built up at that point, whereas a filter positioned directly after the pump will need a high-pressure rating.

Yet pressure isn’t the only consideration; filtration efficiency also matters. The more efficient a filter is, the fewer particulates it allows through. However, high efficiency restricts flow, while low efficiency allows more contaminants through.

It would be easy to think that choosing a filter with a high efficiency will protect components, because fewer harmful particles make it through the filter. But most pressure filters and return filters have a bypass function. This means that if the filter becomes too clogged or the filter is too efficient and slows the flow, a valve opens up within the filter to allow unfiltered oil through – to protect the system and its expensive components from damage through insufficient oil flow and damage through pressure build up.

As you can clearly see, it’s a delicate balance between effective filtration and choking the system through over-efficiency. It’s essential that any replacement filters are chosen according to both efficiency and pressure values recommended by the machine’s manufacturer.

And because different filters feature their bypass either in the element or the head, you must also replace like-for-like in design structure: if the worn filter has its bypass in the head, your replacement filter must also have its bypass in the head, for instance.

Would you like more information about working with hydraulics? Look no further! Our hydraulics staff are always ready to help.