Balancing Mower Blades- A Key to best Performance and Safety for your Customer

We understand that your customers' lawns hold great importance, and providing them with optimal and comfortable lawn care guidance is paramount for their satisfaction. We'd like to draw your attention to a crucial aspect that can significantly impact both the performance of their equipment and their overall experience – the management of vibration

Over time, mower blades can develop imbalances due to damages or regular wear and tear. Incorrect sharpening practices can also lead to imbalance, resulting in uneven cuts, potential damage to their mowers and discomfort while working. As their trusted dealer, it's essential to emphasize the significance of blade balancing to ensure their safety and the longevity of their equipment.

Here are key points to share with your customers:

Understanding The Consequences of Excessive Vibration

Excessive vibration in lawnmowers and brushcutters affects both equipment performance and user satisfaction. Share these key points with your customers:

- Comfort and Performance: Highlight discomfort and fatigue caused by vibration during operation. Recommend balanced blades and anti-vibration gloves for a smoother experience.

- Equipment Longevity: Explain how unchecked vibrations accelerate wear, increasing maintenance costs and reducing equipment lifespan. Suggest blade balancing and regular maintenance.

- Safety Focus: Emphasize vibration's impact on control, potentially leading to accidents. Excessive vibration can make it challenging for the operator to maintain a steady grip on the brushcutter. This loss of control can cause the tool to jerk or move unexpectedly, leading to potential accidents or injuries. Propose balanced blades to enhance operator safety.

- Eco-Friendly Approach: Discuss environmental effects like emissions and noise. Advocate balanced blades for a quieter and more sustainable lawn care routine as vibrating blades impact sustainability by accelerating equipment wear, leading to frequent replacements and increased resource consumption. This results in higher energy use, environmental waste, and resource depletion. Mitigating vibrations through proper maintenance and equipment use promotes longer lifespan, reduced energy consumption, and a more environmentally responsible approach.

- Regulation Awareness: Educate customers on vibration exposure standards, showcasing compliance commitment.

Recognizing an Imbalance of the Blade

Educate your customers on how to identify an imbalance through noticeable vibrations during mower operation and uneven lawn cuts. Unusual noises or a loss of power and efficiency are also indicators to inspect the blade closely. During a visual inspection, guide them to look for visible damages, cracks, notches, or significant deformations, as these may indicate severe imbalance issues.

Important: Emphasize that in cases of severe damage, the blade should be completely replaced to prevent further issues.

The Right Timing for Vibration Checks

Advise your customers to perform vibration checks before commencing seasonal tasks, ensuring a smooth and trouble-free start. For those engaged in professional landscape maintenance, periodic checks throughout the season, based on usage frequency, can be beneficial.

Expanding the Scope of Vibration Management

Encourage your customers to extend the principles of vibration management beyond mower blades. A low vibration trimmer line can lead to improved fuel efficiency or battery endurance, enhancing overall operational sustainability. Watch our video to explore the benefits. Additionally, incorporating the use of anti-vibration gloves and regular balance assessments not only enhances user comfort but also contributes to quieter and more environmentally-friendly operations.

Necessary Tools and Equipment

- blade balancing tool

- protective gear (goggles, cut-resistant gloves, and hearing protection for grinding)

- a grinder or angle grinder with a flap disc

- a socket wrench set.

Step-by-Step Balancing Process

- Turn off the machine.

- For petrol lawnmowers, disconnect the spark plug connector and tilt the mower at a maximum 46° angle backward to prevent motor oil from entering the air filter (or lift it completely). Electric mowers can simply be turned upside down.

- Remove the blade using protective gloves and goggles (Use our socket wrench set).

- Clean the blade thoroughly.

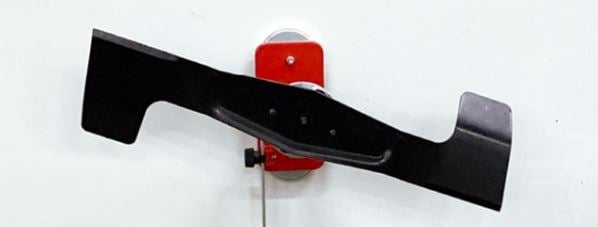

- Mount the blade on a test device on the wall.

- Position the blade

- Check the balance of the blade

- Use an auxiliary rod for a more precise result.

Blade Balancer

Blade BalancerIf the blade leans to one side, instruct them to sharpen the side that tilts downward, focusing only on the cutting edge and not other areas of the mowing bar.

Sharpening mower blade

Sharpening mower bladeAfter sharpening, have them re-check the balance using the blade balancing tool.

Mower Blade before Balancing

Mower Blade before BalancingTip: Advise them to slightly tap the blade and wait for it to come to a standstill during the balancing process.

Mower Blade after Balancing

Mower Blade after BalancingImportant: Emphasize that in cases of severe damage, the blade should be completely replaced to prevent further issues.

Have a look in the Kramp webshop for well balanced lawnmower blades>>

Emphasize the Importance of Maintenance

Regular cleaning and inspection of lawnmowers are essential for prolonged satisfaction. To guarantee your customers safety and receive expert assistance, we recommend they consult a specialized dealer like yourself. Should any of their mower blades become imbalanced, emphasize the importance of careful sharpening, taking note of the optimal grinding angle, which is approximately 30°.

Safety should never be compromised. Encourage your customers to equip themselves with suitable work gloves and protective goggles during the sharpening process. To guarantee the effectiveness of the sharpening, suggest they verify their results using a blade balancing tool. Should they come across cracks or significant notches, emphasize the need to replace the blades entirely to avoid potential damages.

An interesting Tip to Share with your Customer

Did you know that using chalk on the blade can enhance sharpening precision? Acting as a lubricant, it aids in identifying craters and irregularities more effectively. However, they should ensure the blade is thoroughly cleaned before applying the chalk.

Any Questions?

By offering these valuable tips to your customers, you will not only enhance their lawn mowing experience but also reinforce your reputation as a knowledgeable and customer-oriented dealer. Thank you for your dedication to providing excellent service, and please feel free to reach out to our product specialists or send an email to Knowledge Center if you need any further assistance. You don't have a Kramp account and look for products mentioned in this article? Then find a dealer near you.