A torque wrench is a special kind of wrench that is used to tighten nuts and bolts to an exactly determined torque value. A torque wrench has a square tip that fits all commonly used sockets. It is a sophisticated measuring tool that is essential to the quality of the work being performed.

How to make optimum use of a torque wrench

A torque wrench is a sensitive measuring tool. By taking good care of it and making sure it is serviced by experts, you can have the satisfaction of using it for years. When using a torque wrench, you should be aware of the following points:

- Torque wrenches are not intended for loosening nuts and bolts.

- A torque wrench becomes unreliable if you regularly exceed its set value.

- Do not overtighten nuts or bolts (using a pneumatic wrench, for example) before applying the correct tightening torque with a torque wrench. It should still be possible to tighten things. If you hear a click right away, the tightening torque is too high and the torque wrench will have undergone unnecessary strain.

- You should preferably work with two hands. Use one hand to keep the socket or other attachment in place while using the other to slowly perform the required turning movement.

- The rule of thumb is "tight is tight". Always turn the torque wrench slowly until it clicks. Making it click again will have a negative effect on your construction.

- Immediately release the tension from the torque wrench before storing it away. If the wrench remains at the set tension, the internal spiral spring will be pushed in for too long, which gradually shortens it. Even as little as a fraction of a millimetre will affect the accuracy!

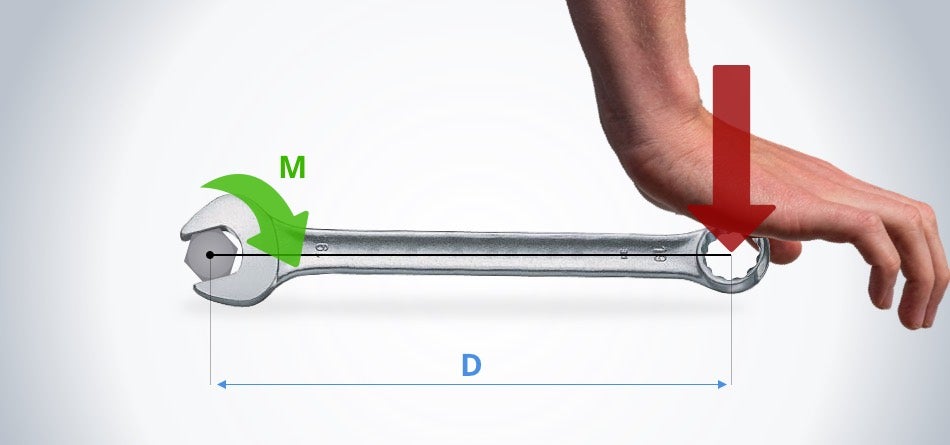

- Make sure that you know the bolt's tightening torque. This is the torque (force x arm) you may use to tighten the bolt. The tightening torque is expressed in newton metres (Nm). If we imagine that you are using a force (F) of 10 kg to push down on the end of a 1-metre double open end spanner (d), you will be creating a torque (M) of 100 Nm (10 kg = approx. 100 N). But as this is not possible in practice, you will be using a torque wrench to tighten the bolt in a controlled manner. When the set value is reached, you will hear or feel a click.

- A bolt that has been lubricated can be tightened with less force, so the required tightening moment is also reduced compared to a bolt without lubricant. Conversely, the same bolt without lubricant—with a higher friction coefficient—will require a greater tightening torque. This demonstrates that it is highly important for you to know the friction coefficient. If you do not, there is a risk of the bolt not being tightened or the thread being damaged. For new and unlubricated bolts, a friction coefficient of µ 0.14 is often used.

Target values

For bolts with a different head geometry, you may use no more than 80% of the tightening torque as a target value. Example: M12, quality 10.9 = 125 Nm x 0.8 = 100 Nm

Testing torque wrenches

Torque wrenches are subject to the ISO standard for hand torque tools (ISO 6789). This means that companies operating on the basis of the ISO standard are required to have their tools tested every year. You will then receive a test certificate, allowing you to prove this to companies if an audit is performed. Kramp can help you to arrange these annual tests. If you would like to have one arranged, complete the repair form in our webshop, clearly indicating in the description what needs to be done.

If you have any other questions about torque wrenches, please contact our product specialists. Or view the Kramp torque wrenches in our webshop.