How often should you service your PTO shafts and why is servicing so important?

In the world of agriculture, ensuring the safety, longevity, and operational efficiency of drive shafts and machines is paramount. However, this task can be quite challenging due to the wide range of machines and implements used by farmers and contractors. These machines often come equipped with different Power Take-Off (PTO) shafts, making it difficult to keep track of maintenance requirements and suitable spare parts. Yet, proper maintenance is the key to long service life and high operational reliability.

The Solution: Walterscheid Connected Service (WCS)

If you have already come across our article on extending the life of a PTO drive shaft, you'll understand the challenges of PTO shaft maintenance. Walterscheid now offers a revolutionary digital maintenance assistant solution known as Walterscheid Connected Service (WCS). This innovative system provides a complete and permanent overview of PTO shaft maintenance needs wirelessly through your smartphone.

Clear Advantages

Time Saving: WCS simplifies daily maintenance work, saving valuable time for farmers and contractors.

Increased Lifetime: Regular maintenance, guided by WCS, significantly extends the lifetime of PTO drive shafts, reducing the need for replacements.

Savings on Lubricants: WCS ensures that lubricants are applied when needed, reducing costs and environmental impact.

Automatic Recording: WCS Counter automatically records operating hours, helping users stay on top of maintenance schedules.

Easy Identification: Each PTO shaft is equipped with a unique QR code (WCS ID) for easy identification and tracking.

Digital Checkbook: The WCS Assistant allows for digital documentation of maintenance actions, creating a comprehensive maintenance history.

The Significance of PTO Shaft Maintenance

You may already have read our article on how to extend the lifespan of a PTO drive shaft.The PTO shaft is responsible for transferring mechanical power from your tractor to attached implements. Its vital role carries significant force that can lead to complacency among users. Tragically, injuries and fatalities still occur annually in Europe due to PTO shaft incidents, primarily entanglement and unexpected separations during machine use.

The key to safer operation is regular PTO shaft servicing. To emphasize this importance, we've teamed up with Walterscheid, PTO shaft experts, to discuss maintenance for enhanced safety.

Highlighting the PTO Shaft Guard

Before delving into PTO shaft maintenance, it's crucial to highlight the PTO shaft guard, also known as the PTO shield. This protective cover encases most of the shaft, preventing clothes, bootlaces, or objects from snagging and causing accidents. Regular inspection of PTO shaft guards for damage or malfunction, such as dents, looseness, or misalignment, is essential to ensure safety.

How Often Should a PTO Shaft be Serviced?

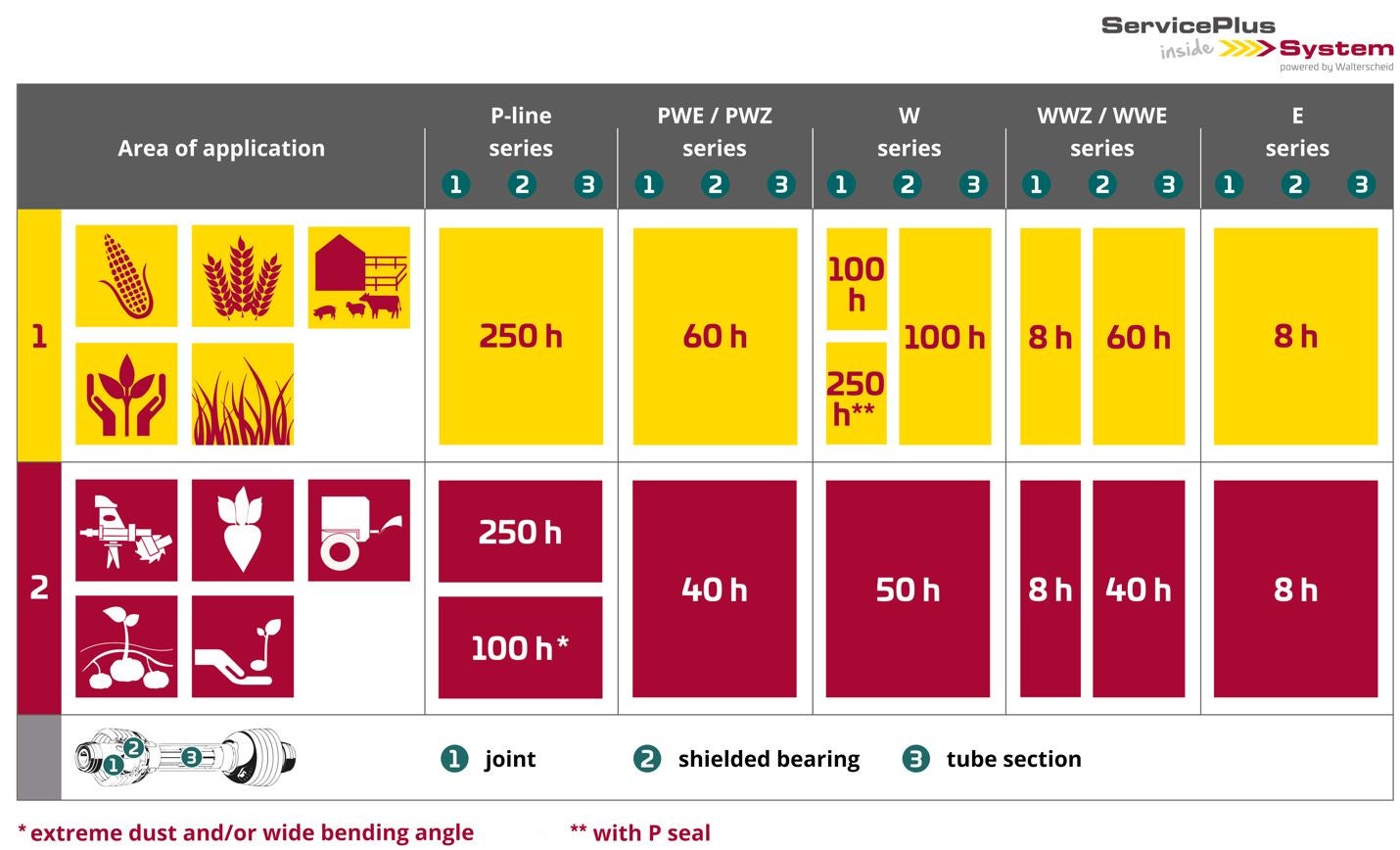

Servicing your PTO shafts is a crucial aspect of ensuring safety and longevity. The frequency of service can vary based on factors such as the manufacturer, shaft model, and specific usage. Some may require fresh lubrication as often as every 8 hours of use, while others can go up to 250 hours before needing it. The range of maintenance intervals can be extensive.

Fortunately, Walterscheid has introduced the innovative "ServicePlus System," which simplifies maintenance intervals and recommends servicing based on hours of operation, specific to different models and their applications. This system can reduce maintenance efforts for certain power take-off shafts by up to 70%, enhancing safety and efficiency.

Application-Specific Maintenance

The ServicePlus System is exclusive to Walterscheid products, ensuring safe and efficient maintenance intervals for PTO shafts. For users of PTO shafts from other manufacturers, guidance should be sought at the time of purchase.

Incorporating the Walterscheid Connected Service Assistant into your PTO shaft maintenance routine is highly recommended. This digital solution offers substantial benefits, including efficient servicing, reliability, maintenance cost savings by up to 94%, and environmental friendliness. It's your key to hassle-free, cost-effective PTO shaft maintenance, enhancing the overall efficiency and reliability of your agricultural operations.

Any Questions?

You’ll find a range of Walterscheid PTO shafts in the Kramp web shop, and this article on choosing the right PTO shaft will make the buying process simple. For questions on any farming equipment from all of our suppliers, there’s no better source of advice than your Kramp specialist or send an email to Knowledge Center. If you want to purchase any mentioned products but you don't have a Kramp account, find a Kramp dealer near you.