Agri dealer Broekens from the Netherlands works with Microsoft Dynamics Navision. They created their own EDI link with suppliers. Pieter IJpma, the forward-thinking warehouse manager explains to us how important automation is in Broekens’ daily operation.

“Our desire to make as few mistakes as possible set us in motion. Our connection had to be as simple as possible. New Holland offered a ready-made system, but it was difficult to get other suppliers involved. We have been working with Microsoft Dynamics Navision since 2011, so our system manager wrote a code for an EDI connection himself.”

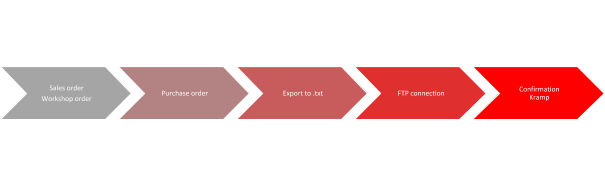

Easy steps

Pieter explains: "Every purchase order is created from a sales or workshop order. These orders are already filed in the system. An export button is used to create a .txt file, which we can easily drag and drop to the FTP link. The link is being read every 5 minutes and after 15 minutes we receive a confirmation. Kramp's webshop is only used to look up items and help customers at the counter. "We don't use the shopping cart anymore!”

Warehouse overview

The biggest advantage of the integrated link? Transparency and data. Pieter continues: "We have the complete company in focus, from stock to sales to margins. This makes us less vulnerable. Suppose someone falls ill, then everything is up to date and easy to pick up by a colleague. This even allows us to work from home, should it be necessary. The insights also lead to more efficient operations. We want to reduce our obsolete and overstock. All data is available in the system, so it's a matter of analysing and adjusting.”

Organisational support

Everyone within Broekens has to work with the system. Colleagues at the three other Broekens locations are also familiar with the system. "It can be difficult to change old habits, both in the workshop and in the warehouse. But it is also in the workshop manager's interest to be able to match the orders with the machines. That enables him to book the hours on the right machines," says Pieter. "and reduces the chance of mistakes.”

Shifting focus

Automation means saving on administration. An example: in the near future, invoices will be automatically matched with purchase orders. For Pieter, this means that he can outsource other tasks to his colleagues at the administration desk, giving him more space for new activities. For example, he wants to spend more time on Kramp Online Service and visit Broekens' service points in the region more often.

Automation requirements

What more does Pieter wish for? "We would like even more connections between our own system and suppliers and even better insight into practice. As far as purchasing is concerned, I want to take a few steps out and as a company we want to work in a more customer-oriented way using CRM.”

Focus on the horizon

In 2022, Broekens is ready for a new software package. Together with a taskforce, Pieter is already orienting. "We have put a mark on the horizon and are researching how other organisations are tackling it. For example, we are looking at companies in other sectors that are already more advanced in automation, such as the truck industry. This is where we get our inspiration.” It's clear that Broekens takes a thorough approach. "We are looking from our own wishes and needs, in combination with the available systems.”

Broekens is one of the oldest mechanisation companies in Friesland (the Netherlands). From four locations they have been serving the agricultural sector for over 160 years with new and used agricultural machines, earthmoving machines, tractors and spare parts. They are dealers of New Holland, Krone and Dewulf. Broekens is a real family business and is now led by the 5th generation.