Spray smart: increase flexibility with DynaJet pulse-width modulation (PWM)

Precision farming requires a wide variety of spraying techniques and applications. Spray techniques, both when using self-propelled and trailed sprayers, experience fluctuations in travel speed. Operators speed up or slow down as conditions demand. These speed variations result in pressure and spray quality variations. How can pulse width modulation (PWM) technology tackle these? And what are the benefits of PWM technology?

What is pulse-width modulation (PWM)?

TeeJet uses pulse-width modulation (PWM) technology with solenoid operated tip shutoffs allowing the operator to control tip flow rate and droplet size, independent of driving speed. That means you can work with high speed while maintaining accuracy. What are the other benefits of PWM?

- Improve sprayer productivity by maintaining a constant application rate over a wider range of ground speeds.

- Select and maintain a constant droplet size across a wider range of speeds and pressures without changing tips.

- Minimize drift and maximize coverage by maintaining the optimum droplet size.

- Vary the capacity of your spray tips from the cab. There is no more need to manually change nozzles when wind is coming up or another flow is needed. The capacity of your spray tips and drift / droplet size can be controlled from the cab.

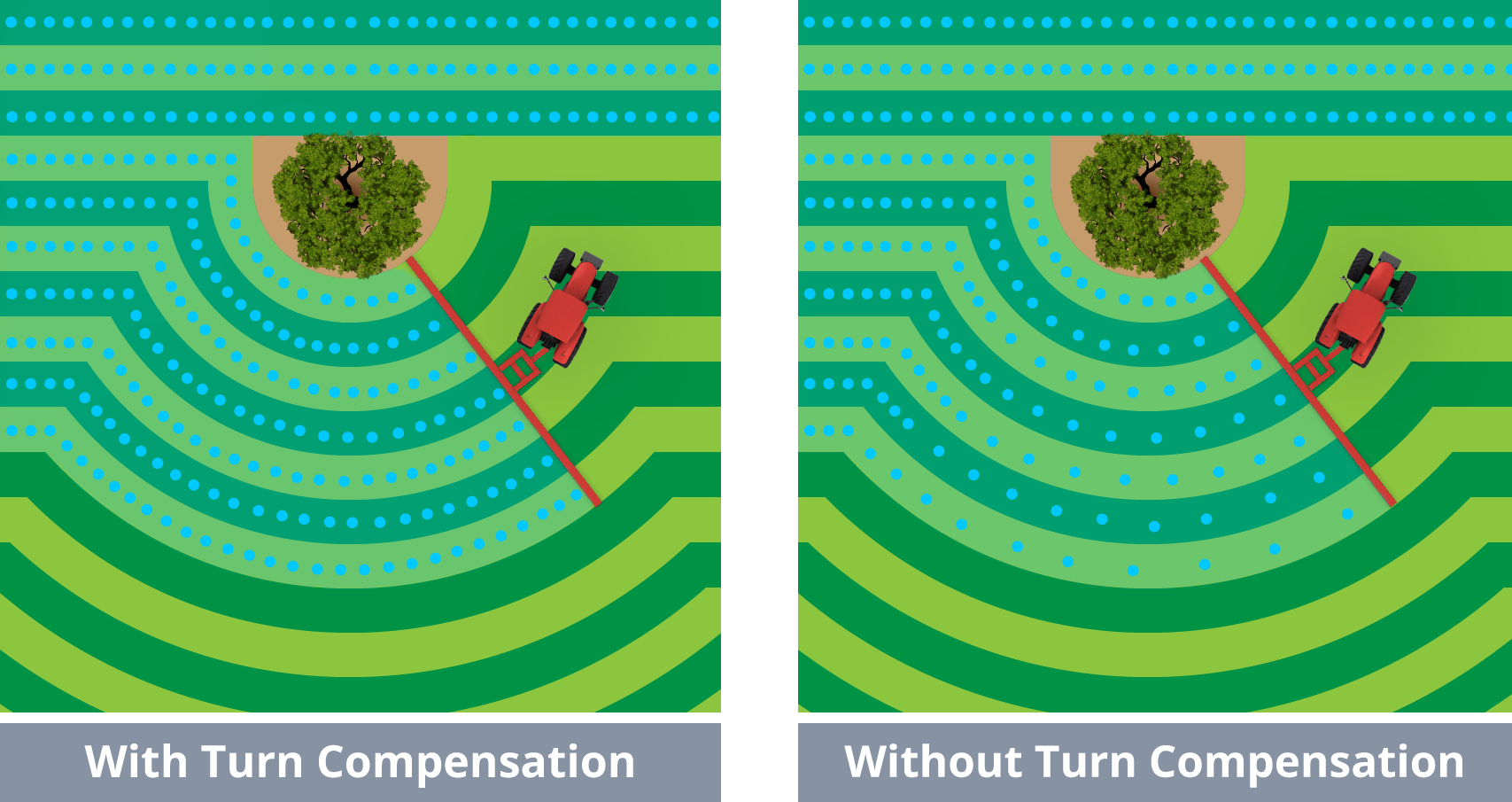

The image above shows the turn compensations of the PWM system.

The image above shows the turn compensations of the PWM system.Introducing: TeeJet DynaJet

Keeping the right balance between the driving speed and the working pressure is key. The DynaJet system offers three key benefits:

- Flexibility

More spray hours, no more nozzle changing. It allows the operator to adjust the “size” of your spray tip from the seat of the cab allowing you to maintain your target application rate across a wider range of ground speeds. It allows you to select the most appropriate droplet size for your application and maintain this droplet size across a wider range of ground speeds. For example: normally a nozzle can handle 2,4 liters per minute, with the Dynajet you have the possibility to variate from in capacity. If you use an 06 nozzle with at 3 bar 2,4 L/min, the DynaJet offers you a flow range of 0,75-2,4 L/min. This is like realising an 03-04-05 and 06 capacity with 1 nozzle.The driver can easily set the desired droplet size via the compact standalone touchscreen or an isobus User Terminal. - Spray quality

- More consistent spraying and more consistent drop size. For example in hilly landscapes or small fields with many corners.

- Changing drop size if wind comes up.

- Turn compensation for better spray quality in turns of when driving around obstacles.

- Hardware ready for the future

The system is ready for the future. With the right combination of of task controller, rate controller and DynaJet, variable rates within the boom width, gnss based individual nozzle control and spot spray applications are possibilities.

DynaJet® Smart Droplet Management. No need to compromise between speed and spray quality.

Ready for the future: gear up!

Spray nozzles are highly engineered, precision components. They play a crucial role in the application of your crop protection products. Do you want more information about this subject? Contact our specialists.