There are numerous variations of saw chains which are mainly determined by different chain pitches, lengths, and widths. The size of the saw and the length of the cutting set play an important role. Depending on the application requirements and preferences, it is therefore important to make the right decision when buying a chainsaw.

Chain Pitch

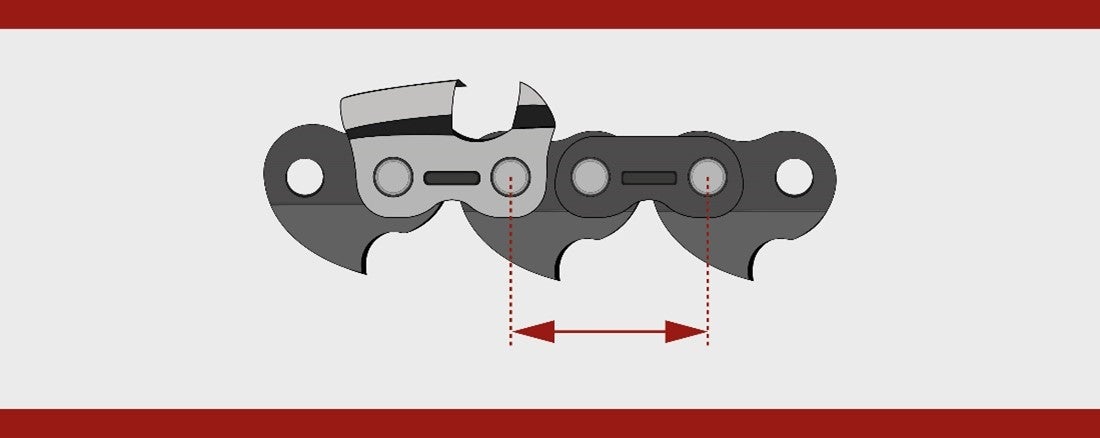

The size of the chain is also called the chain pitch and is given in inches. To determine the size, measure the distance between three consecutive rivet pins, each from the centre of the rivet, and divide this value by two.

How to determine the chain pitch

How to determine the chain pitchThere is a suitable chain pitch for every application. We have listed the pitches available on the market in the following table.

| Pitch (in inches) | Characteristics |

| 1/4'' |

|

| 3/8'' Low Profile (LP) |

|

| 3/8'' |

|

| .325'' |

|

| .404'' |

|

Chain Length

The length of the chain is determined by the number of drive links. The number of drive links needed depends on the length of the guide bar. Some manufacturers print the information directly on the product - so it is worth taking a look at it to get reliable information about the required chain length.

Tip: If the information is no longer legible or not printed, the length can also be determined by counting the drive links. The best way to do this is to lay the chain flat on its side and mark the first link where the counting starts.

Drive Link Thickness

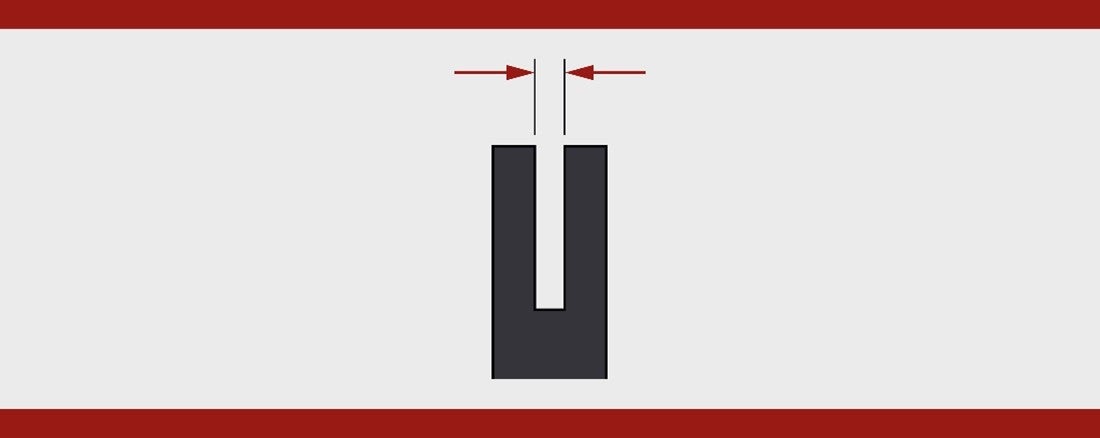

The width of a chain is defined by the drive link thickness, i.e. the groove width of the guide bar. This means that the width of the groove and the thickness of the drive link must absolutely match, otherwise, the chain cannot be guided and driven safely.

Common chain widths on the market are: 0.043" (1.1mm) / 0.050" (1.3mm) / 0.058" (1.5mm) / 0.063" (1.6mm).

How to measure the drive link thickness

How to measure the drive link thicknessTip: If the thickness of the drive link is not indicated on the guide rail? Use a calipers to measure the thickness of the drive link.

What Else Is There to Know?

The two main types of chain are half or full chisel. Depending on the field of application and preferences, the two variants are distinguished from each other: The main difference is the shape of the cutting tooth.

Half Chisel

- Cutting tooth shape is rounded

- Suitable for wood that is contaminated with sand or gravel.

- Cutting time longer compared to full chisel

- Constant power with a fine cut

Full Chisel

- Cutting tooth shape is angular and pointed

- professional use

- clean wood (without contamination such as gravel or sand)

- faster cutting time

- due to more aggressive cutting behavior quicker blunt and coarse cut

Safety Chains

When working with especially light chainsaws, kick-backs can occur more quickly. It is therefore advisable to use a saw chain with safety drive links. The additional elevation is in front of the depth limiter and guides the wood softer and less aggressively. Safety chains ensure low kickback which ensures pleasant and above all safe working.

Tip: If, despite the safety chain, there is increased jerking during work, the distance between the cutting unit and the safety link should be checked. If, for example, the distance is too great after sharpening, the work will be more aggressive and the height of the safety link will have to be adjusted.

Saw Chains for Particularly High Demands

Carbide chains are particularly robust and stable saw chains. They are mainly used for rescue saws and special applications. Due to the reinforcement of the cutting mechanism, the chain is characterized by a particularly long service life. However, a specialist dealer must always be consulted when resharpening this sort of chain.

Kramp offers another robust variant with the titanium-coated saw chain. Thanks to the robust coating, it remains sharp for a particularly long time, especially when the cut material is contaminated. This happens especially with stock wood or after logging from the forest.

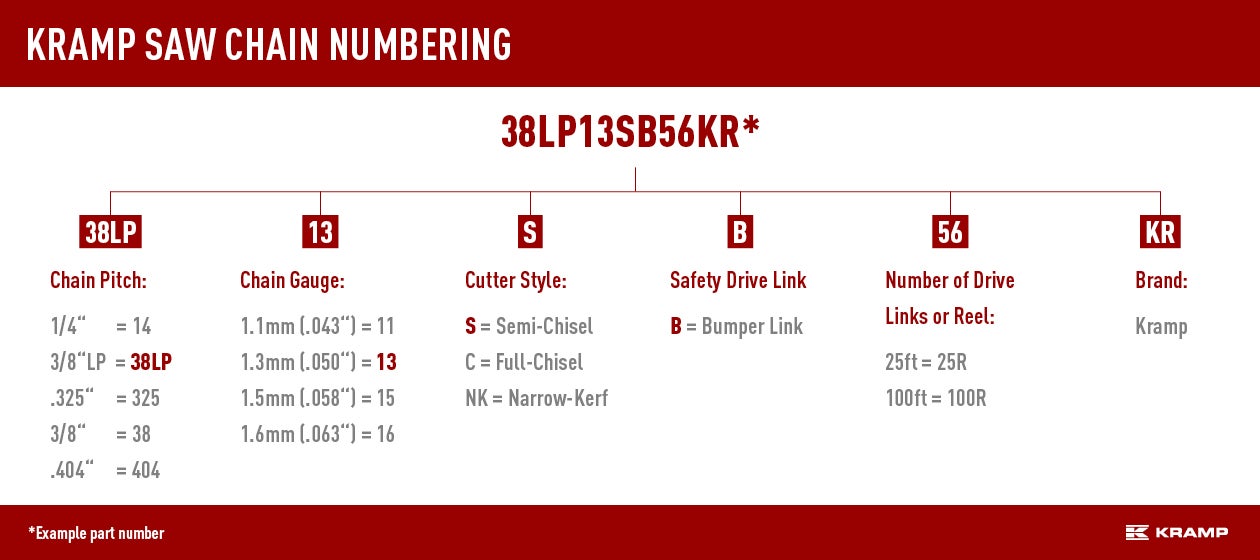

Use the graph down below as a guide to find the right saw chain for your chainsaw.

Conclusion

Cutting sets should be replaced at regular intervals to avoid accidents and ensure consistent quality. The choice of chainsaw and chain depends on one's own preferences but also on the purpose of use. A full chisel chain is particularly efficient for professional use. For more universal use, it is best to use a half-chisel chain. The choice of safety drive links should be made based on the application and your own abilities. In any case, you should grind and oil the chain regularly to ensure a long product life.

Do you have more questions about chainsaw chain maintenance?

Please contact a product specialist or contact us by sending an email to knowledgecenter@kramp.com.