The Nine Most Common Causes of a Faulty V-Belt and How to Avoid Them

V-belts are a very important element of machinery drive systems. It is vital to check the tension before, during and after the season. What are the most common problems with V-belts and how can you fix them quickly and easily? Find out in this article!

Problem 1: Belt Breaks Shortly after Installation

If the belt breaks shortly after installation, there are several possible causes:

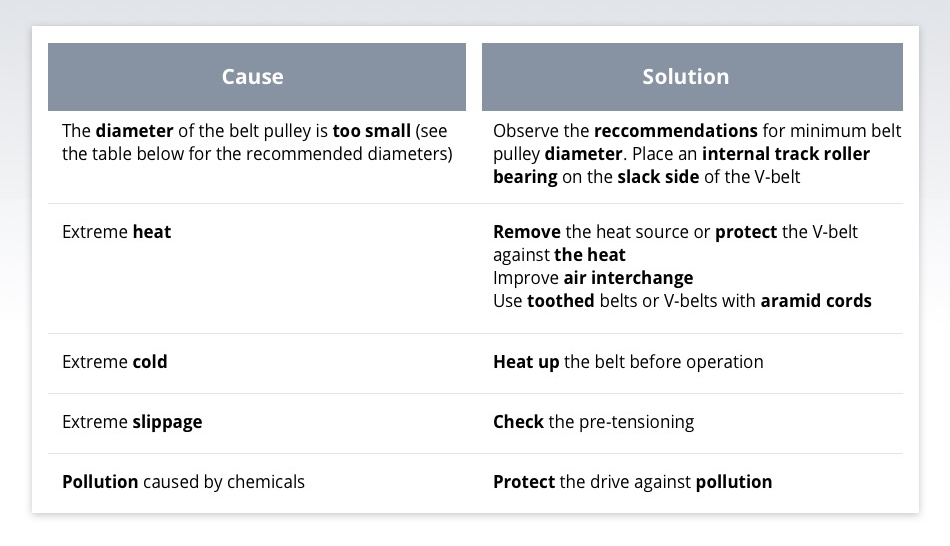

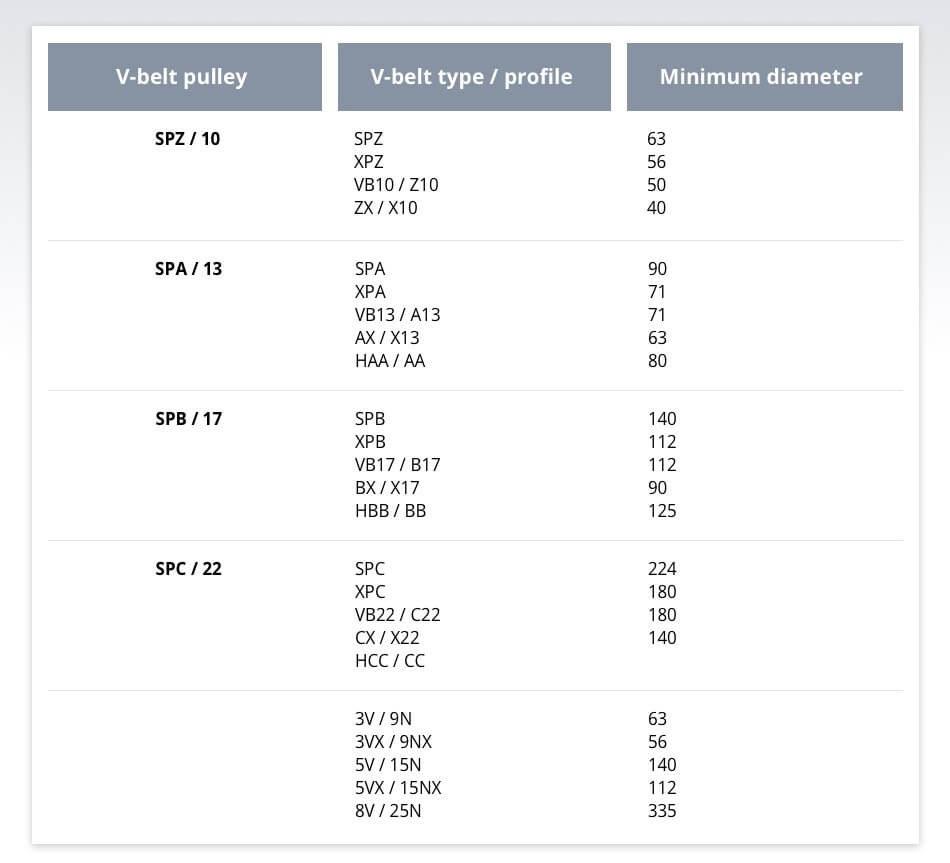

Problem 2: Cracks on the Outside of the Belt

Cracks occur when the diameter of the belt pulley is too small (see table below), pollution (Contamination would be more used here and the table below) has been caused by chemicals or one of these conditions applies: extreme heat, extreme cold or extreme slippage.

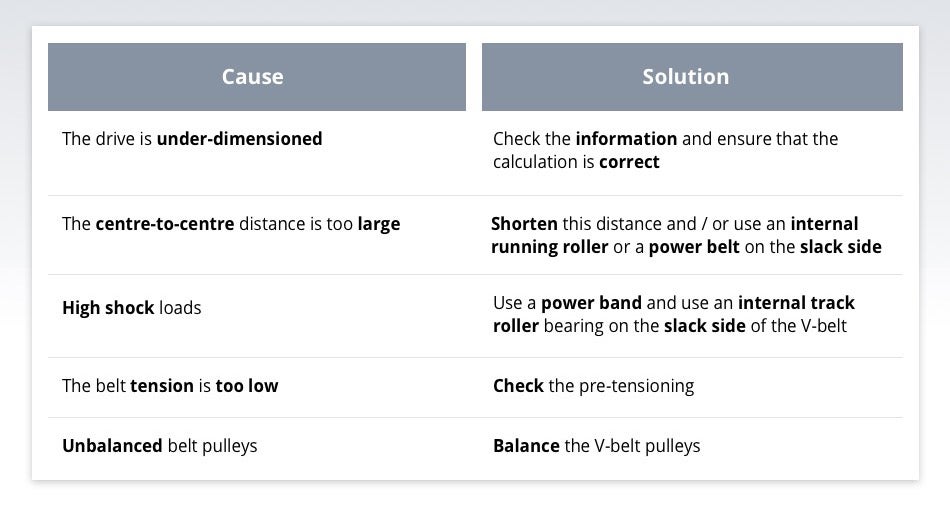

Problem 3: Extreme Vibration

There can be many causes for belt vibrations, including an under-dimensioned drive, the centre-to-centre distance between the shafts being too large, high shock load, the belt tension being too low or unbalanced belt pulleys.

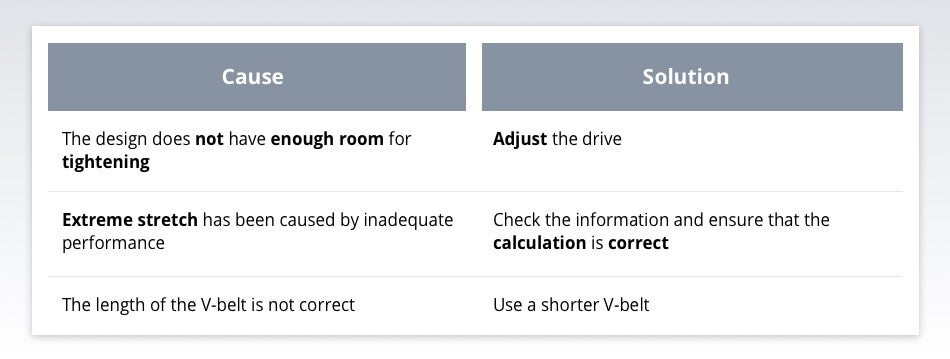

Problem 4: Belts Cannot be Tightened Further

If there is insufficient space in the design, if extreme stretch has been caused by inadequate performance or if the length of the v-belt is not correct, it will not be possible to tighten the belts further. The solution? Find out where the error is, determine the correct length for the V-belt and replace the V-belt if necessary.

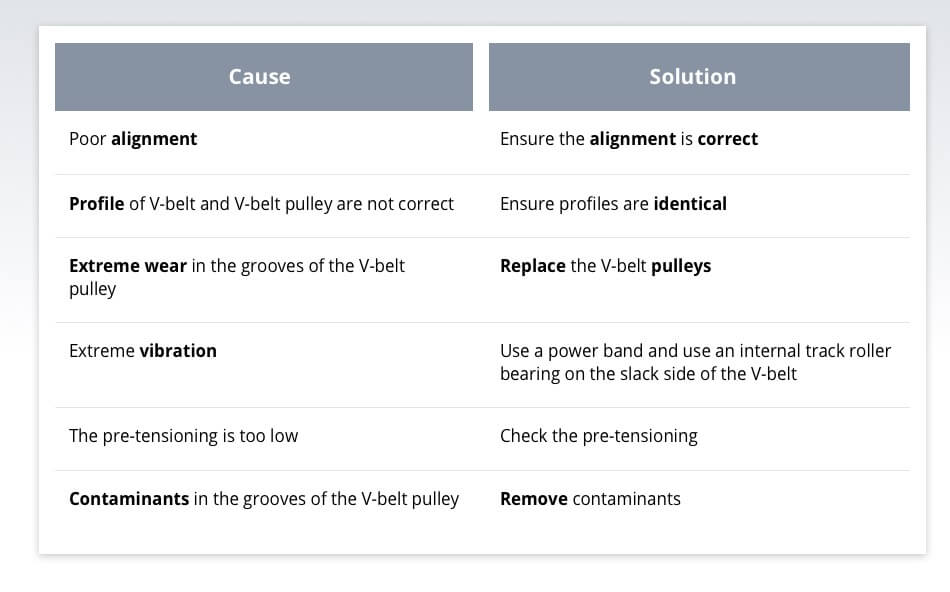

Problem 5: V-Belts that Become Reversed or Jump out of the Groove

V-Belts may become reversed due to poor alignment, extreme wear in the grooves of the V-belt pulley, extreme vibration, the pre-tensioning being too low or contaminants in the grooves. This can be prevented by good maintenance:

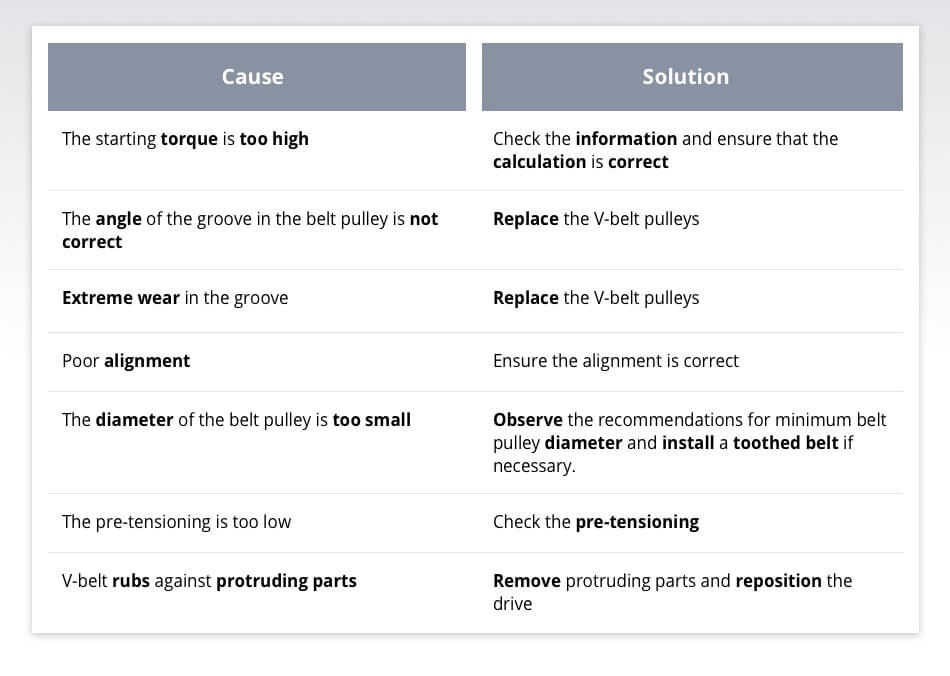

Problem 6: Extreme Wear on the Sides of the V-Belt

There are numerous reasons why extreme wear can occur. Check all of these things and if necessary, install a toothed belt or reposition the drive.

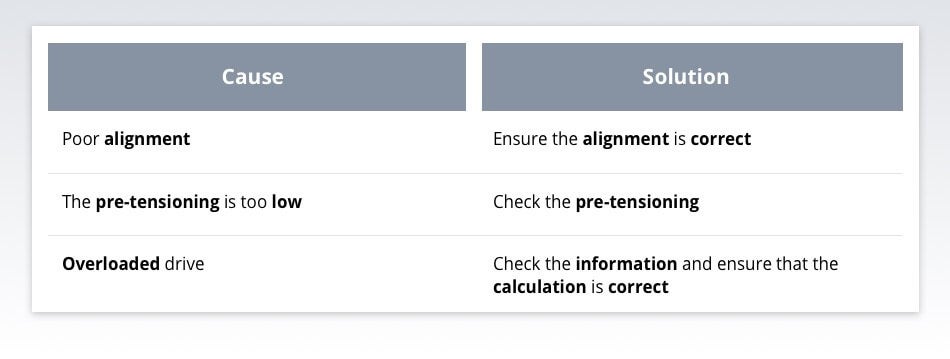

Problem 7: Extreme Noise

A common problem is an unusual or extremely loud noise. Any expert can tell you that this can be caused by poor alignment, the pre-tensioning being too low or an overloaded drive. Check the information and adjustment and ensure that calculation is correct — you can do this yourself, or you can request the assistance of an expert.

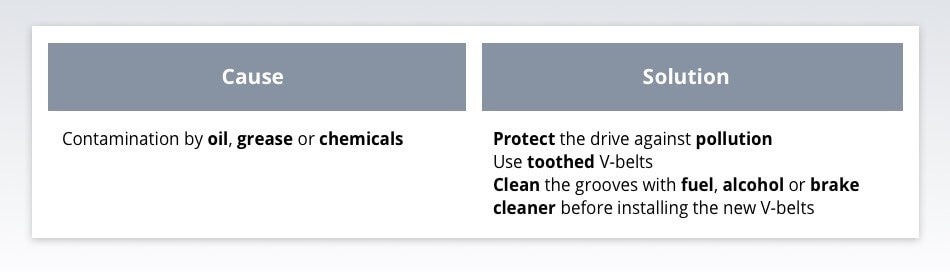

Problem 8: V-Belt Expands or Becomes Soft and Sticky

Contamination by oil, grease or chemicals can cause the V-belt to expand or become soft and sticky. Protect the drive against contamination!

Problem 9: V-Belts Stretching Unevenly

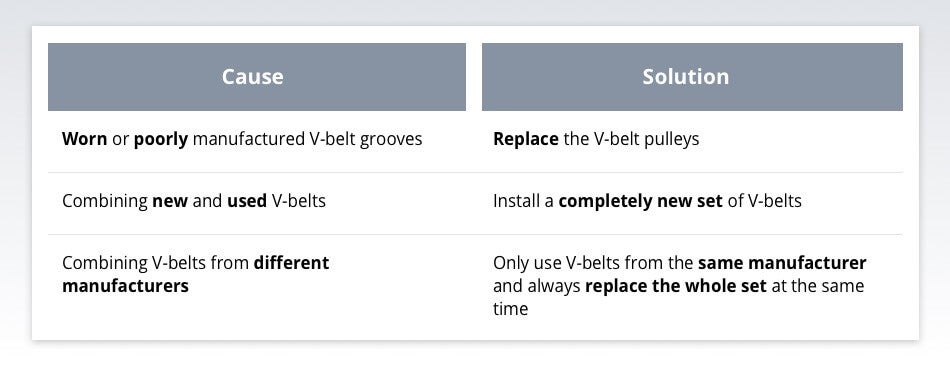

V-Belts stretching unevenly can be caused by worn or poorly manufactured V-Belt grooves, by combining new and used V-Belts or by combining V-Belts from different manufacturers.

The solution? Always install a completely new set of V-Belts from the same manufacturer and with the same type number. This helps you to avoid any issues!

Regularly Check for Damage

Please note: V-belts do not just wear out during busy seasons. The most common cause of damage to V-belts is simply ageing of the material. The belts lose their elasticity and the fibres lose their strength. It is therefore better not to wait for visible damage to be present, but to check the belts regularly and to test them for strength. After replacing the V-belt, it is necessary to set the tension again and to check the tension after switching the machine off.

Are you doing the job yourself? In this article we offer some advice on how to do this and how to choose the right belt.

Do you have more questions? Please contact one of our product specialists, find a Kramp dealer near you or contact us at knowledgecenter@kramp.com.